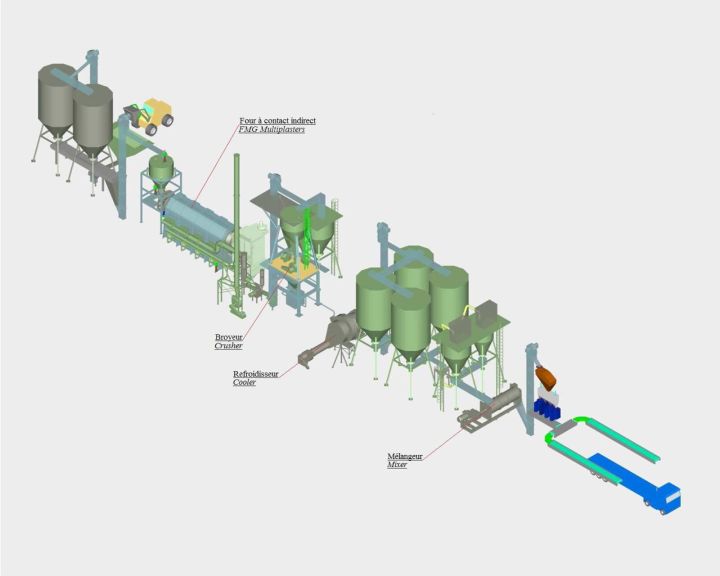

PLASTER PROCESSING - GRELBEX® SOLUTIONS

CRUSHING - GRINDING

The crushing and the grinding determine two basic steps which condition the optimization of the calcinations unit. Our equipment adjusts the gypsum particle size and controls the feeding flow at GRELBEX® kiln's inlet.

GRELBEX® jaw crusher allows the products fragmentation by crushing between two jaws: one fixed and one mobile driven by an eccentric shaft coupled to an electric motor.

GRELBEX® hammer crusher allows the materials reduction by percussion effect with the mean of articulated hammers and rotating to high speed in an armored grinding chamber. The discharge products calibration is ensured by removable bars grid with adjustable space.

CALCINATION - CUISSON

The calcination unit is the heart of the process. GRELBEX Technologies offers different technologies to meet your requirements:

- For all your kinds of plasters, GRELBEX Technologies recommends its Four Marmite GRELBEX FMG MULTIPLASTERS GRELBEX with indirect contact operating by batch or its kiln with direct contact.

For the FMG kiln, the heating is carried out by burners. The fumes circulate in the space between the rotary drum and the fixed surrounding wall. The heat is transmitted to the product through radiation of the drum wall by convection and by conduction. The plaster constituted essentially of semi-hydrate calcium sulfate [CaSO4. ½ H2O] is obtained by gypsum partial dehydration at a calcination temperature between 150 to 190°C to eliminate up to 16 % of water.

For the kiln with direct contact, the operation is provided with the same gypsum particle size as this of the FMG Multiplasters Kiln (0 - 300 mm). The gypsum is dehydrated to a temperature of 550°C. The production capacity of overcalcined plaster is 70 tons / day.

- For high-end alpha plaster for medical and industrial applications, the autoclave kiln is a calciner under pressure.

- For beta plaster intended to prefabrication and construction plasters industry, GRELBEX Technologies recommends its CYCLONE kiln.

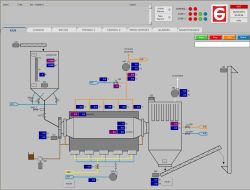

AUTOMATISM - ELECTRICITY

For the management and the supervision of your plant, GRELBEX Technologies proposes a complete and personalized range of services:

- Integration of the main brands: Schneider, Siemens, Omron, Rockwell… to fit to your requirements

- Automatism and electric layout study.

- Electric switch cabinets and wiring diagram carrying out.

- Programming (PLC and supervision).

- Commissioning.

This service is proposed for all your kinds of plants (plaster, fertilizers, waste processing…).

Especially for your plaster plants, discover our supervision application WingypsⓇ: for the production control of your different plasters, this application software allows to survey and pilot the plant in all simplicity and is delivered with PC support and printer.